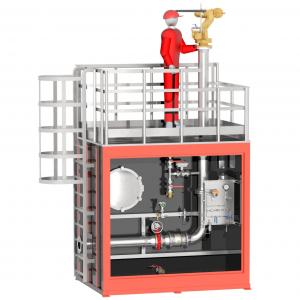

Firewater monitor and valve skids

Firewater monitors are used where it is not practical or desirable for a traditional deluge system with overhead deluge nozzles. Firewater monitors have a large flow capacity (1500 lpm to 7000 lpm+), cover a large area (150m2 – 700m2), and their nozzles are adjustable from a jet to wide fog pattern. Depending on the water source capacity, firewater monitors can reach 60 – 90 meters in a jet pattern.

FPE Sontum offers monitors as miscellaneous fire equipment wherein the monitor is shipped loose and assembled in the field or within monitor valve skids wherein the monitor isolation valve is an Inbal deluge valve controlling the downstream flow and pressure. Monitors can be operated manually, remotely, or self-oscillating. Remote operation via remote control panel and electric motors allows an operator to control the monitor in a safe area. Oscillating monitors utilize the firewater supply to drive a Pelton water motor to oscillate the monitor in a pre-set horizontal and vertical position without operator interface. Due to the close proximity of the monitor to a fire on an offshore platform the oscillating and remote control design has been preferred.

A monitor nozzle pre-set in the jet position is a risk to personnel in close proximity when the monitor is activated as the force of the jet stream can cause serious injury. FPE Sontum’s standard monitor nozzle is an FPE Sontum design wherein the nozzle returns to fog position once the operation is complete thus removing the jet stream hazard. Additional information for FPE Sontum’s nozzle can be found under product area ” Nozzles and adaptors”.

FPE Sontum designs monitor valve skids to meet the demanding requirements of the oil and gas industry. The standard design is AISI 316 stainless steel cabinet with associated valves within and the monitor mounted on top. All piping less the monitor / nozzle is of titanium construction.

FPE Sontum offers monitor valve skids with foam application to fight flammable liquid fires. Foam application rates can be 1% or 3% dependent upon the project and FPE Sontum has designs for operation with a pressurized foam supply or local foam tank.

Project design specifications consistently change. Therefore, FPE Sontum offers options for CuNi or Super Duplex SS piping, cabinet insulation with heater for cold weather, or a platform for manual operation of the monitor. Where possible the monitor and nozzle can be specified by the project. Click on the following models to review their specific design data and options.