Deluge and Sprinkler Systems

Deluge Systems are named from the ’deluge’ of water they provide when activated. The most basic Deluge System consists of only 3 parts: Deluge control valve, distribution pipework and Deluge Nozzles.

Deluge Systems are normally considered the main fire fighting system on an Offshore Installation or other oil and gas installation. Two very important forms of protection are provided: Fire (flame) extinguishment and cooling.

Foaming agents can be added to the water, such as AFFF (Aquous Film Forming Foam), which is very effective against Hydrocarbon (= Oil, Gasoline etc.) pool fires.

Cooling is used to protect structural members and equipment from heat radiation, due to an ongoing fire, so that major damages and fire propagation is avoided.

The Deluge Nozzles are evenly spaced above the ”floor” area they protect (i.e. Total Flooding), and fitted to the distribution pipework (grid), which in turn is fed from the Fire Mains via the Deluge Control Valve.

Alternatively the Nozzles may be positioned around specific equipment (a.k.a. Local Protection), such as Transformers, Pressure Vessels or Valves / Flanges, to provide dedicated protection.

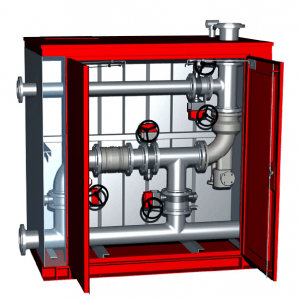

Deluge Skids can be built in many different ways as single – or multivalve skids and with various types of foam inducting systems.

A number of Data Sheets showing various types of deluge valve skids and various piping configurations can be found hereunder. These skids are some few examples of a large variety of deluge valve skids we have built. Some of the various models shown on the attached examples have a certain type of foam mixing devices. Other types of foam mixing devices could be used in the same lay-out configuration.